PermaLife is a large-scale mycomaterials production project financed by the european union’s life program.

THESE INNOVATIVE ENVIRONMENTALLY FRIENDLY MATERIALS ARE MADE FROM ORGANIC URBAN WASTE TRANSFORMED LOCALLY BY THE NATURAL ACTION OF MYCELIUM.

PermaLIFE aims to respond to a double problematic of urban areas :

Coffee grounds, organic waste or sawdust, PermaLIFE produces innovative, circular and natural myco-materials on a large scale. They have unique characteristics that make them capable of replacing polluting plastic materials and styrofoam in the fields of packaging.

Organic waste

Organic waste is increasing year after year. This represents CO2 emissions (1 kg of organic waste = 775 g of CO2) as well as a significant economic cost. For example, on a global scale, the management of coffee grounds represents a cost of more than 3 billion euros per year. This management of bio-waste is also essential to reach the 65% recycling target set by the European Union for 2035.

Insulation

The extraction of raw materials for packaging or insulation materials (e.g. plastic products, glass wools, rock wools) consumes fossil fuels, requires transportation and transformation that consume a lot of energy and contaminates water. These insulating materials are also difficult to recycle. For example, 1m2 of mineral wools represents CO2 emissions of 16.99 kg

Plastics

Every year, 8 million tons of plastic end up in the oceans. The North Pacific Ocean is the most impacted. It is also found in nature and in our bodies. The cumulative global production of plastic to date amounts to 7.8 billion tons. It is therefore essential to find other innovations that will slow down this production. 1 kg of polystyrene (example: frigolite) = 7.4 kg of CO2

Mycelium as resource

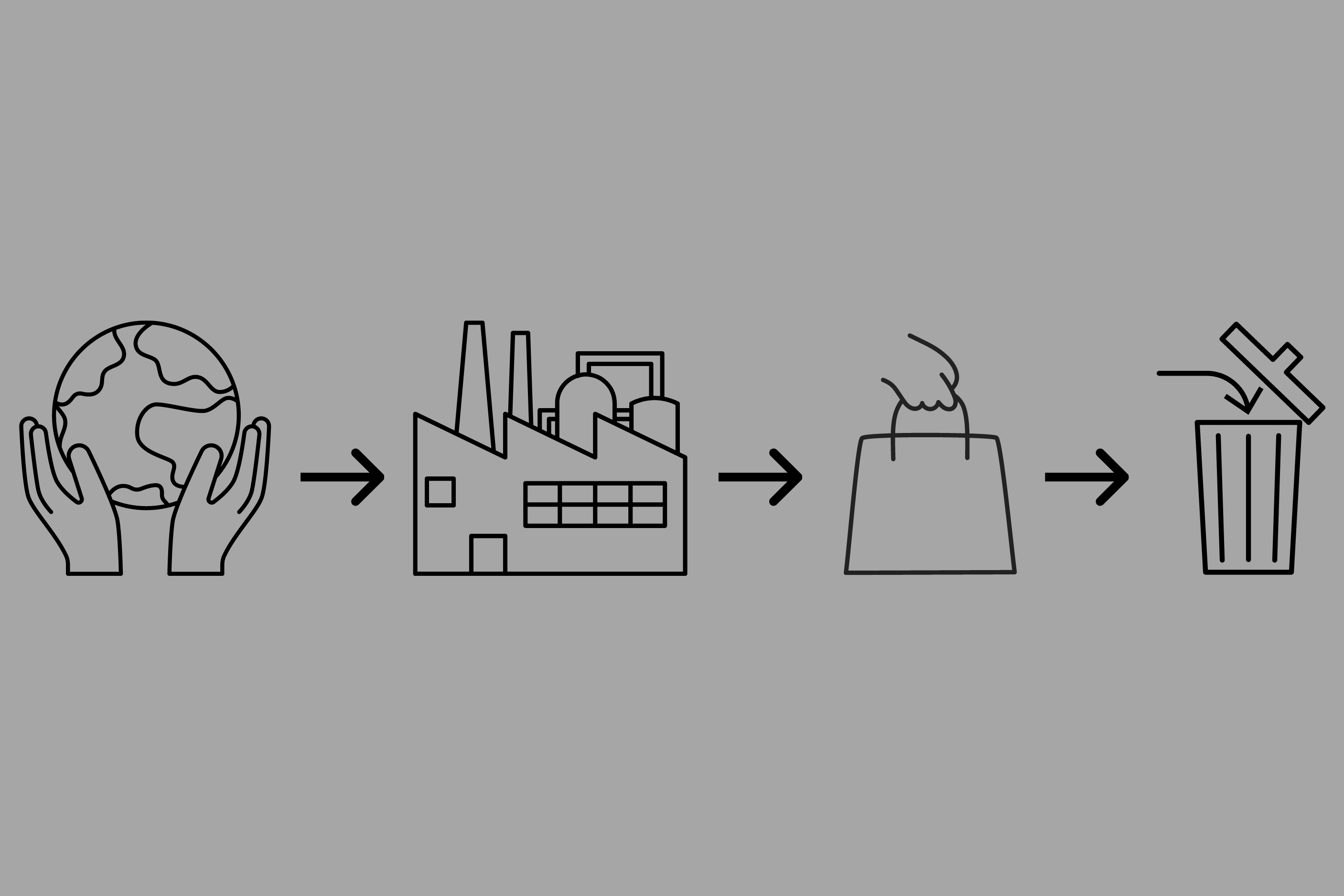

Replace polluting materials such as plastic and mineral wool with environmentally-friendly materials made of mycelium.

A large-scale production line

Build an automated myco-materials production line for packaging industries.

Upcycling urban waste

Recycling urban waste such as coffee grounds, sawdust and organic waste into innovative materials.

Soft chemistry instead of petrochemistry

Produce materials based on the natural chemistry of mycelium to free ourselves from fossil fuels.

Creation of rewarding and sustainable jobs

Reintroduce productive activities in urban areas to create local, rewarding and sustainable jobs, particularly for people who are under-valued by the job market.

Competitive myco-materials prices

Be competitive with current polluting materials to represent a sustainable alternative.

Contribution to the circular economy and the bio-materials sector in the European Union.

IMPACTS DURING THE FIVE YEARS OF PRODUCTION AFTER THE PROJECT

Reduction of CO2 emissions

The project will save 2400 tonnes of CO2, equivalent to 20 million km by car or 2,400 round-trip passengers from Brussels to New York.

Reduction of unmanaged organic waste per year

Over 500 tonnes of organic waste will be upcycled. Waste that would otherwise have been buried or incinerated.

Job creation

The project will create around twenty rewarding, sustainable jobs in an urban area for people who are far away from the job market.

Pollutants avoided

Over 400 tonnes of high-carbon products in the packaging sector will be replaced by the same quantity of natural, local and circular products.

Cost-efficient business

Thanks to European funding, the project is targeting profits from 2026 on revenues from myco-material sales alone.

EXPECTED OUTCOMES

14,8tons of myco-materials per month

5000kg of recycled waste per month

January 2023

Launch of the PermaLIFE project and recruitment

June 2023

Permafungi equips the Belgian Pavilion at the Venice Biennale

February 2024

Production protocols and plans for the new production site

August 2024

Lauch of works on the new site

September 2025

Start of production of 3.7 tons of myco-materials per month

December 2025

Increase in production capacity to 9 tons of myco-materials per month and recruitment

June 2026

Cruise speed reached and recruitments

Our future production site is coming together!

Work on our mycomaterials production site is well under way.

With the arrival of high-quality machinery and the refurbishment of the building,

we’re proud to see it all taking shape.

The installation of sterile areas, the arrival of our autoclave, soon the installation of photovoltaic panels, and so on.

This ambitious project constitutes a crucial step in our development,

enabling us to increase our production capacity and improve our infrastructure,

to better meet the growing demand for mycomaterials.

We look forward to sharing our progress with you and working in this state-of-the-art facility.